Beranda / Produk / By Manufacturer / SMC / SMC Industry 4.0

The SMC Industry 4.0 SIF-400 training system simulates a highly automated smart factory, including Industry 4.0 technologies, advanced manufacturing concepts, and the reality of the connected enterprise.

Main features:

•Connected and open system

•Plug & Play

•Flexible

•Modular

•Real process

•Management software

•IIoT (Industrial Internet of Things)

•Ideal for academics and research

The HAS-200 system reproduces a production process with a high level of automation which helps to develop the professional capacities required in diverse sectors (automotive, semiconductors, food, pharmaceutical, etc.).

Aspects such as aesthetics, user motivation and the development of transversal skills (such as teamwork etc.) have also been taken into account in the conception and design process.

At university level, the HAS-200 system represents a powerful development platform for research projects.

The SMC Industry 4.0 HAS-200 Special Edition system with more technologies of Industry 4.0 allows the development of the most demanded skills in a highly automated environments of Industry 4.0. This technologically advanced didactic equipment allows the acquisition of the required skills for the different professional sectors.

In addition to the technologies implemented in the standard edition of this system, the special version includes additional technologies that make this equipment the ideal solution to emulate the reality of a smart factory with the latest 4.0 technologies.

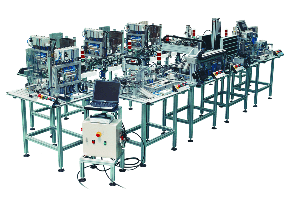

The training equipment, FMS-200 special edition – Industry 4.0, is the advanced mechatronics learning system for INDUSTRY 4.0.

In addition to the technologies implemented in this system’s standard version, the special version includes extra technologies enabling users to expand their knowledge of Industry 4.0 technologies, as well as to be trained on advanced mechatronics.

The modular features of this flexible automation cell enables the introduction of variations in its stations so that they adapt to the different requirements of companies and training centers. From a simple configuration of one station only (working fully autonomously) to a complex configuration with eight stations, the possibilities are endless.

All the components in the FMS-200 Special Edition – Industry 4.0 are used in industry, so that the user works with real elements at all times making the learning process more meaningful.

The system enables integrating robotic technology, where it is possible to choose between incorporating a collaborative, or standard, industrial robot. In addition, FMS-200 Special Edition – Industry 4.0 includes the breakdown simulation system which generates up to 16 different breakdowns to be diagnosed by the user.

The FMS-200 Industry 4.0 special edition system is an open platform for developing the user’s own projects. The control panel is completely modular and can be rapidly disassembled so the user can design and integrate a new control.

The different process stations assemble a turning mechanism. To provide the system with greater flexibility, stations adapt to a wide variety of assemblies, introducing variations in the materials, colours and part sizes. The combination of all these possibilities means that a total of 98 different assemblies can be obtained enabling the use of production management strategies.

Training equipment in mechatronics with Industry 4.0 technologies.

Develop the skills most in demand for 4.0 technologies and be prepared for the new challenges presented by Industry 4.0.

The SMC Industry 4.0 FAS-200 SE I4.0 system offers professional training according to the industrial reality, simulating a real assembly process and including different technologies from Industry 4.0. This system consists of an automated flexible assembly cell with five different stages:

Assembly

Handling

Quality inspection

Transfer

Warehouse and shipment

FAS-200 SE I4.0 has been designed as compact equipment for the development of the skills most in demand in Industry 4.0 technologies affecting mechatronics and robotics.

This special edition of the FAS-200 comes in two configurations, where the central cap transfer station can include either pneumatic technology or collaborative robotic technology.

Business Park Kebon Jeruk

Blok F2 No. 9

Jl. Raya Meruya Ilir No. 88

Meruya Utara

Jakarta 11620

Tel. +62 21 5859365

Fax. +62 21 5859268

www.dynatech-int.com

Jika Anda ingin berlangganan daftar email kami, silakan masukkan email Anda di bawah ini